How Stackable Storage Containers Improve Warehouse Efficiency and Workflow

In modern warehouse environments where speed, organisation, and accuracy are essential, the efficiency of storage systems plays a major role in operational success. As businesses handle increasing volumes of goods due to rising e-commerce demands and diverse product ranges, choosing the right storage solution becomes critical. Among the most practical and effective tools supporting warehouse efficiency are plastic storage containers and stackable storage containers, designed to assist in storing, sorting, transporting, and protecting products across all stages of the supply chain.

These containers are engineered to maximise available space, improve handling convenience, and enhance inventory control. Whether used in distribution centres, manufacturing plants, logistics fleets, or industrial storage facilities, their role has become central to optimising workflow and reducing operational costs. For warehouse managers looking to streamline systems and improve productivity, investing in high-quality storage containers delivers significant benefits across the board.

The Importance of Effective Storage in Warehousing

A well-organised warehouse directly influences efficiency, safety, and turnaround time. Poor storage methods can result in lost inventory, damaged goods, workflow delays, and safety hazards. By implementing reliable containment and management tools such as plastic storage containers, organisations ensure controlled handling of items with reduced risk.

These storage solutions provide structure and visibility, allowing employees to locate products faster, handle materials more safely, and reduce unnecessary labour time. In industries where every second and every square metre matter, optimising resources becomes essential.

Why Plastic Storage Containers Are Used in Warehouses

Unlike cardboard boxes or wooden crates, plastic storage containers offer long-term durability and reusability, making them cost-effective for continual industrial use. They are designed to withstand frequent movement, heavy loads, moisture exposure, and stacking pressure all essential qualities for a busy warehouse environment.

Top advantages of plastic storage containers in warehouses include:

- Long-lasting construction with high impact resistance

- Moisture and dust protection for sensitive goods

- Easy cleaning and sanitisation

- Lightweight yet strong structural performance

- Reusable, reducing packaging waste and replacement expense

These benefits make plastic containers a preferred choice for modern industrial handling.

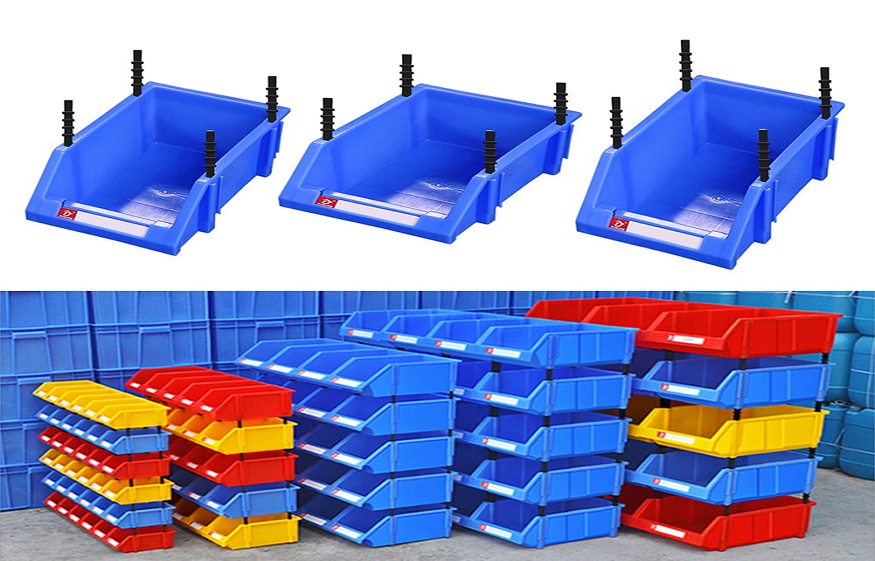

The Space-Saving Power of Stackable Storage Containers

Space is one of the most valuable assets in warehousing. Poorly designed storage systems waste floor area, increase travel paths, and complicate inventory management. Stackable storage containers are engineered to solve these challenges by allowing vertical organisation that makes full use of available height.

Key benefits of stackable storage containers include:

- Maximum use of vertical space without compromising stability

- Safer stacking that prevents collapse or product damage

- Improved aisle flow and reduced congestion

- Faster access to stored goods with easily labelled fronts

- Better transport efficiency for trucks and pallet systems

When containers can be stacked neatly and securely, warehouses can store more within the same footprint avoiding costly building expansions or offsite storage rentals.

Applications in Warehouse Operations

Stackable and plastic storage containers support almost every stage of warehousing workflows including:

| Stage | Role of Storage Containers |

| Receiving | Sorting and separating incoming goods |

| Put-away | Systemised placement by category or SKU |

| Order Picking | Efficient picking routes with labelled containers |

| Packing & Dispatch | Transporting goods to shipping areas |

| Reverse Logistics | Handling returns and repairs |

They also integrate well with automation systems, conveyors, pallet racking, and mobile equipment such as platform trolleys and pallet jacks.

How Storage Containers Improve Inventory Accuracy

One of the biggest challenges in warehousing is maintaining accurate stock records. When products are stored loose or in unlabelled boxes, errors increase dramatically. Stackable storage containers offer consistent sizing, which supports barcode systems, lot identification, and structured stock rotation.

Better accuracy means:

- Fewer picking mistakes

- Reduced time searching for items

- Better supply chain forecasting

- Faster stocktaking and cycle checks

This contributes directly to customer satisfaction and profitability.

Choosing the Right Warehouse Storage Container

When selecting storage containers for warehouse operations, consider:

- Load capacity and material strength

- Stackability and interlocking design

- Size compatibility with shelving and pallet systems

- Ventilation needs

- Colour coding or clear visibility options

- Lid type and security features

Choosing the right style ensures safety, productivity, and long-term cost savings.

Conclusion

From optimising space to improving inventory accuracy and workflow speed, plastic storage containers and stackable storage containers have become indispensable in warehouse operations. Their strength, durability, and modular capability support efficient handling processes that reduce labour demands and keep goods safe throughout the storage cycle.

As logistics industries continue to scale and demand for rapid delivery grows, effective storage solutions will remain one of the most important investments facilities can make. For any business looking to improve organisation, streamline movement, and maximise space, reliable stackable storage systems are a smart choice with measurable long-term benefits.